Vacuum Meat Blender

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Tianjin |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Tianjin |

Model No.: ZKJB-650

Brand: Helper

Applicable Industry: Food &Amp; Beverage Factory, Farms

Out-of-warranty Service: Video Technical Support, Online Support, Field Maintenance And Repair Service, Spare Parts

Status: New

Types Of: Sausage

Degree Of Automation: Automatic

Place Of Origin: China

Warranty Period: 1 Year

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Pump, Gearbox

Core Selling Point: High Rigidity

Voltage: 380V

Customized: Customized

Material: Stanless Steel

Type: Meat Mixing

Application: Meat Processing And Sausage Making

| Selling Units | : | Set/Sets |

| Package Type | : | Seaworthy wooden case |

The Key Factors for High Quality Vacuum Food Mixer

1. The structure of the mixer must be reasonable, and the materials can be mixed uniformly in the shortest time. Helper's Vacuum Mixer adopts Paddle and spiral belt design, which can quickly mix various materials.

2. The mixing box of the mixer adopts an arc design, so as to achieve the effect of low mixing resistance and low temperature rising of the material. Helper's vacuum mixer adopts U-shaped mixing box.

3. The material and thickness of the cabinet should meet the requirements. Helper’s vacuum mixer is made of 304 stainless steel, with thickened steel plates and reinforcing ribs to ensure that the equipment will not be deformed under long-term vacuum and negative pressure working conditions.

4. The mixer is easy to load and discharge. Helper’s vacuum mixer adopts an automatic elevator for feeding and automatic unloading through a pneumatic device, which reduces the labor intensity of workers and improves work efficiency.

5. The realization of various additional functions of the mixer. Helpe's vacuum mixer can realize automatic weighing function, automatic water filling function, refrigeration and stirring function, automatic cleaning function, steam injection function, etc.

Introduction to 650L Industrial Vacuum Mixer

The vacuum mixer adopts double shaft and helix paddle structure, which will mix raw material in circle movement, to reach the perfect mixing effect. The whole machine is made from stainless steel, which enables the machine to have good reliability, durability, air tightness and convenience to clean. The backward open structure makes it safe and reliable. The parallel double shaft structure and ramp type blades will make the materials at the optimum degree for various process requirements. This machine is the best of same products.

Features of Vacuum Food Mixer

--- Excellent vacuum sealing technology that applied in the whole mixing machine series.

--- The cycloidal gear of this machine makes transmission stable reliable, and low noise.

--- Single and double shaft structure are available for different capacities.

--- It prevents the raw meat to be oxidized damage and reduces the bubbles existing.

--- Auto cover opening and closing and easy material discharging design.

--- Positive and inversive rotation control.

--- Cooling system is an optional for special application.

--- Stainless steel structure and excellent surface treatment make for easy cleaning.

Performance Data of 650L Vacuum Mixer Blender

| Volume(L) | Compressed Air (Mpa) | Mix Speed (RPM) | Power(KW) | Dimension(mm) |

| 650 | 0.5 | 84/42 | 4.5*2+1 | 1553*1300*1568 |

Vacuum Mixer Series

| MODEL | Capacity (L) | Mixing speed(r/min) | Power | weight | Dimensions |

| ZKJB-60 | 60 | 75/37.5 | 1.5 | 260 | 1060x600x1220 |

| ZKJB-300 | 300 | 84/42 | 2.4x2+1.1 | 600 | 1190x1010x1447 |

| ZKJB-650 | 650 | 84/42 | 4.5x2+1.1 | 850 | 1553x1300x1568 |

| ZKJB-800 | 800 | 84/42 | 4.5x2+1.1 | 1100 | 2100x1380x1860 |

| ZKJB-1200 | 1200 | 84/42 | 7.5x2+2.2 | 1760 | 2160x1500x2000 |

| ZKJB-2000 | 2000 | 16-40 Frequency Inveter | 18 | 3000 | 2270x1930x2150 |

| ZKJB-2500 | 2500 | 20-40 Frequency Inveter | 25 | 3300 | 2340x2150x2230 |

View the working process of Industrial Vacuum Mixer

| |

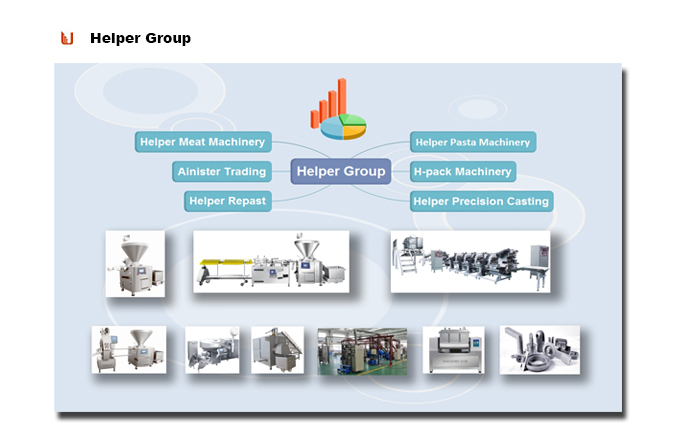

About Helper Machinery Group

Factory Overview---To understand our production capacity and company strength

|  |

|  |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.